A commercial deep fryer is a vital piece of equipment in restaurants, food trucks, and catering businesses. However, over time, carbon buildup can significantly impact its performance, leading to poor food quality, increased energy consumption, and costly repairs. Preventing such buildup is crucial for maintaining optimal frying conditions, extending the life of oil, and ensuring food safety.

In this blog, we'll explore why such buildup occurs, its impact on fryer efficiency, and practical steps to prevent it, helping you maintain your equipment in optimal condition.

Create delicious desserts like waffles and crepes effortlessly with our premium equipment! Check out the Waffle Maker here.

Understanding Carbon Buildup in Deep Fryers

What Is Carbon Buildup?

Soot accumulation occurs when food residues, grease, and oil particles accumulate on the product's heating components, walls, and bottom. Over time, these residues burn and harden, forming a thick char deposit layer that negatively affects fryer performance.

Causes of Such Buildup

Many characteristics are responsible for such accumulation in these products:

- Food Debris Accumulation – Small food particles break off during frying and settle at the bottom, leading to burnt residues.

- Overheated Oil – Excessive temperatures cause oil to degrade rapidly, accelerating carbonisation.

- Poor Oil Filtration – Failure to filter oil regularly allows contaminants to accumulate and form hardened deposits.

- Infrequent Cleaning – Neglecting daily and thorough cleaning routines can lead to grease buildup and soot formation.

- Salt & Seasonings Reaction – Salt and spices interact with oil, breaking it down faster and contributing to residue buildup.

- Prolonged Oil Usage – Reusing old oil beyond its lifespan increases carbon deposits and off-flavours in your gas deep fryer.

- Uneven Heat Distribution – Hot spots in the appliance cause localised burning, leading to carbon accumulation.

- Improper Equipment Maintenance – A lack of regular inspections and upkeep can worsen residue buildup over time.

Effects of Carbon Buildup

Neglecting such accumulation can result in several problems:

- Reduced Heat Efficiency – These deposits act as insulation, preventing proper heat transfer.

- Uneven Cooking – Food may cook inconsistently due to temperature fluctuations.

- Shortened Oil Lifespan – Contaminated oil degrades more quickly, necessitating more frequent replacements.

- Unpleasant Odours & Off-Flavours – Burnt residues can affect the taste and aroma of food.

- Higher Energy Costs – A clogged roaster consumes more energy to maintain temperature.

- Prospective Fire Hazards – Unnecessary accumulation enhances the danger of grease fires.

How to Prevent Carbon Buildup in Your Fryer?

- Regular Oil Filtration

Regular Oil Filtration & Replacement

Oil filtration is one of the most efficient methods of preventing carbon buildup in your commercial deep fryer for sale. Regularly filtered oil removes food remains, burnt residues, and contaminants, stopping them from sticking and creating char deposits.

Best Practices for Oil Filtration:

- Use a high-quality filtration mechanism to clear pollutants.

- Filter oil at least once every day, especially in high-intensity pantries.

- Avoid reusing degraded oil, as it accelerates carbon formation.

- Consider automated oil filtration systems for efficiency.

Additionally, regular oil replacement is crucial. Oil eventually breaks down even with filtration, leading to carbonisation and off-flavours. To preserve food quality, change the oil before it goes to its smoke point.

- Maintain Proper Frying Temperatures

Excessive heat accelerates oil degradation and carbon buildup. Keeping oil within the prescribed temperature range (normally 325°F to 375°F) stops excessive burning.

Temperature Control Tips:

- Use a mechanical thermometer to check the oil temperature.

- Avoid overheating oil, as it leads to faster carbonisation.

- Adjust fryer settings according to the type of food and batch size.

- Ensure consistent temperature recovery after each batch.

- Skim Food Debris Frequently

During frying, small food particles break off and settle at the bottom when you buy gas deep fryer online. If left unattended, these particles burn and contribute to carbon buildup.

How to Skim Effectively:

- Utilise a fine-mesh skimmer to clear floating dust.

- Skim oil after every batch to prevent residue accumulation.

- Avoid overcrowding the appliance, as this can increase food breakage.

- Dispose of excess batter and crumbs before frying.

Get fast cooking and save energy with our power-saving options. Browse our premium Induction Cooktops for more information.

- Use High-Quality Frying Oil

Not all oils are created equal. Selecting high-quality oils with high smoke points lowers carbon accumulation and enhances oil life.

Recommended Oils for Deep Frying:

- Canola Oil has a bland taste and an elevated smoke level.

- Peanut Oil – Perfect for crispy consistencies, resists breakdown.

- Sunflower Oil – Light taste, excellent heat stability.

- Soybean Oil – A cost-effective and widely used oil in commercial kitchens.

Do not use oils with low smoke points, as they degrade more quickly and contribute to soot accumulation. For further information, visit LCE – one of the leading commercial deep fryer suppliers and distributors in Australia.

- Implement a Daily Cleaning Routine

Frequent maintenance stops grease and carbon accumulation from hardening inside the equipment. A daily cleaning schedule ensures long-term efficiency.

Daily Cleaning Steps:

- Clear the oil and try to clean the appliance's interior.

- Use a non-abrasive degreaser to dissolve grease.

- Scrub warming components and walls with a soft-bristled brush.

- Wash comprehensively and dry before reloading with fresh oil.

- Perform Weekly Deep Cleaning

A weekly deep clean removes stubborn deposits buildup, extending the fryer's lifespan.

Weekly Deep Cleaning Process:

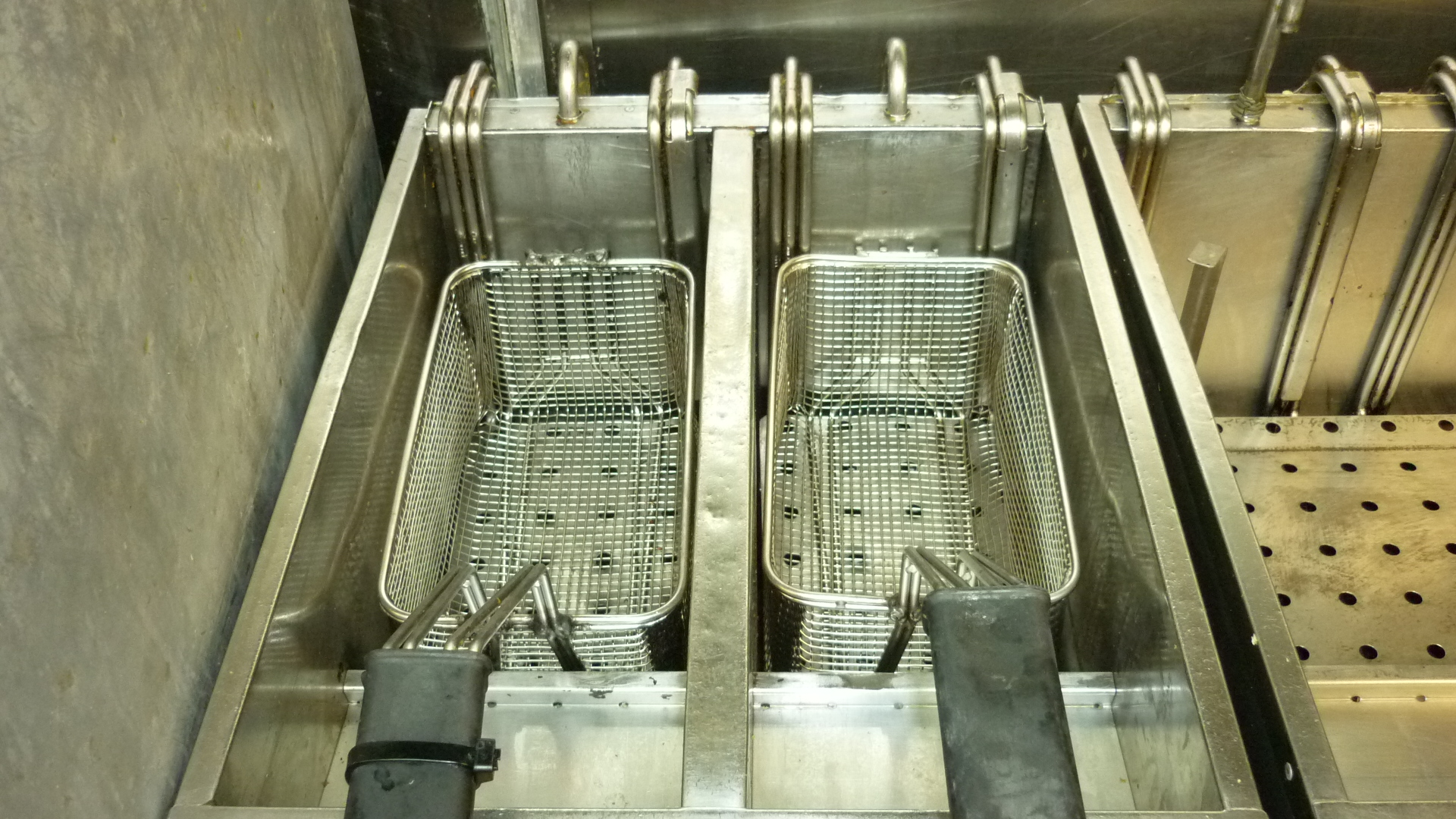

- Remove fryer baskets and racks for soaking and scrubbing.

- Use a boil-out mixture to remove hardened soot buildups.

- Inspect and clean burners, heating elements, and oil tanks.

- Ensure proper ventilation to prevent grease accumulation.

- Avoid Excessive Seasoning in Oil

Salt and seasonings can react with oil, accelerating the degradation and formation of carbon.

Best Practices for Seasoning:

- Season food after frying, not before.

- Avoid directly adding salt to fryer oil.

- Use dry coatings instead of excessive batter.

- Rotate & Replace Oil Regularly

Even with filtration, oil eventually breaks down. Establish a rotation schedule for the product, sourced from top gas deep fryer sellers and manufacturers, to ensure freshness is maintained.

Oil Rotation Tips:

- Replace oil before it reaches its smoke point.

- Use oil testing kits to monitor quality.

- Store oil in a cool, dark area to avoid oxidation.

- Monitor Fryer Performance

Frequent equipment checks help determine early signs of char buildup.

Signs of Residue Accumulation:

- Slow heating or inconsistent temperature recovery.

- Darkened oil with burnt odours.

- Uneven cooking or off-flavours in fried food.

Addressing these issues promptly prevents long-term damage.

- Train Staff on Proper Fryer Maintenance

Educating kitchen staff on best practices ensures consistency in fryer care.

Staff Training Essentials:

- Teach proper oil filtration and skimming techniques.

- Establish daily and weekly cleaning routines.

- Encourage temperature monitoring for optimal frying conditions.

Warm your delicacies and put them on display for customer satisfaction. Check out our range of Food Warmers here.

Best Cleaning Products for Carbon Removal

Using the right cleaning products enhances fryer maintenance:

- Degreasers – Dissolve grease and oil residues effectively.

- Boil-Out Solutions – Break down solidified char buildups.

- Non-Abrasive Brushes – Prevent scratches while scrubbing.

- Oil Filtration Systems – Extend oil life and reduce contaminants.

Conclusion

Preventing carbon buildup in your gas deep fryer is essential for maintaining food quality, energy efficiency, and kitchen safety. By implementing regular cleaning routines, proper oil management, and staff training, you can ensure consistent frying performance and cost savings.